How to use a chain hoist(User guide)

Introduction to chain hoists

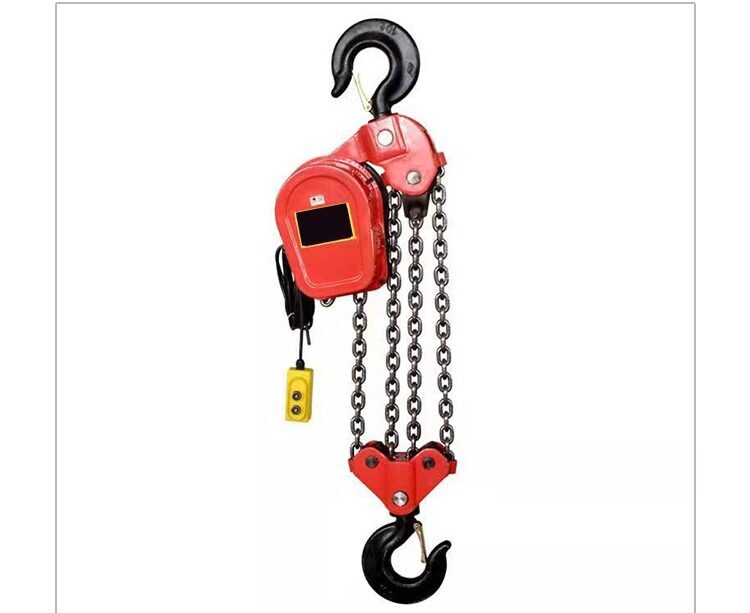

An electric chain hoist is a compact and lightweight lifting device, composed of an electric motor, transmission mechanism, and chain sprocket. It is widely used for material handling in factories, warehouses, docks, construction sites, and other industrial settings.

preparation before use

1.Inspect the equipment condition

- Check the hoist for visible damage or deformation

- Ensure the chain is free from twists, breaks, or excessive wear

- Examine the hook for cracks or deformation

2.Electrical system inspection

- Verify power supply voltage matches equipment requirements

- Check cables and plugs for integrity

- Test upper/lower limit switches for proper operation

3.Installation and Fixation

- Ensure the hoist is securely mounted, and the I-beam rail or fixing point can bear the rated load

- Inspect the running rail for straightness and obstructions

Operating Procedures

1.Power Connection

- Plug the power cord into a compatible power outlet

- Turn on the power switch and verify the indicator light illuminates

2.No-load Operation

- Press the ‘Up’ button and observe whether the chain runs smoothly

- Test the descending function to confirm the braking system operates normally

- If equipped with traveling function, test left/right movement for stability

3.Load Operation

- Align the hook with the load’s center of gravity

- Slowly lift the load, pause at approximately 10 cm above ground, and inspect all components

- After confirming no abnormalities, continue lifting to the desired height

- Maintain smooth movement during load transportation, avoiding sudden stops/starts

4.Completion of Operation

- Place the load steadily at the designated position

- Raise the hook to an appropriate height to avoid obstructing passage

- Turn off the power switch and unplug the power cord

Safety Precautions

1.Overloading Prohibited: Never exceed the rated lifting capacity

2.No Side Pulling: Loads must be lifted vertically to avoid lateral forces

3.Personnel Safety

- No Standing Under Loads: Keep clear of suspended loads at all times

- Maintain Full Attention: Operators must focus completely during operation

4.Abnormal Condition Handling

- Immediately stop operation and inspect if abnormal noise or vibration is detected

- Electrical faults must be repaired by qualified personnel only

5.Environmental Requirements

- Avoid use in damp or flammable/explosive environments

- Implement rain protection measures for outdoor operation

Routine Maintenance

1.Periodic Lubrication: Lubricate chains, gears, and other components as specified in the manual

2.Cleaning & Inspection

- Remove dirt and rust from chains

- Check for loose fasteners

3.Electrical Maintenance

- Keep electrical components dry and clean

- Inspect wiring insulation for integrity

4.Periodic Testing

- Conduct comprehensive monthly inspections

- Perform annual safety certification by authorized agencies

Troubleshooting Guide

1.Motor Fails to Start

- Verify power supply connection

- Check for blown fuses

- Inspect limit switch reset status

2.Chain Jamming

- Check for foreign object obstruction

- Inspect for chain twisting/deformation

- Verify adequate lubrication

3.Brake Failure

- Check brake clearance adjustment

- Inspect brake pad wear condition

4.Abnormal Noise

- Verify gear meshing alignment

- Examine bearing integrity

Summary: Proper operation and maintenance of electric chain hoists not only enhance work efficiency but, more critically, ensure operational safety. Operators must receive professional training to fully understand equipment specifications and operating procedures. Mandatory pre- and post-operation inspections shall be conducted, with immediate corrective actions taken for any identified issues to maintain the equipment in optimal working condition at all times.